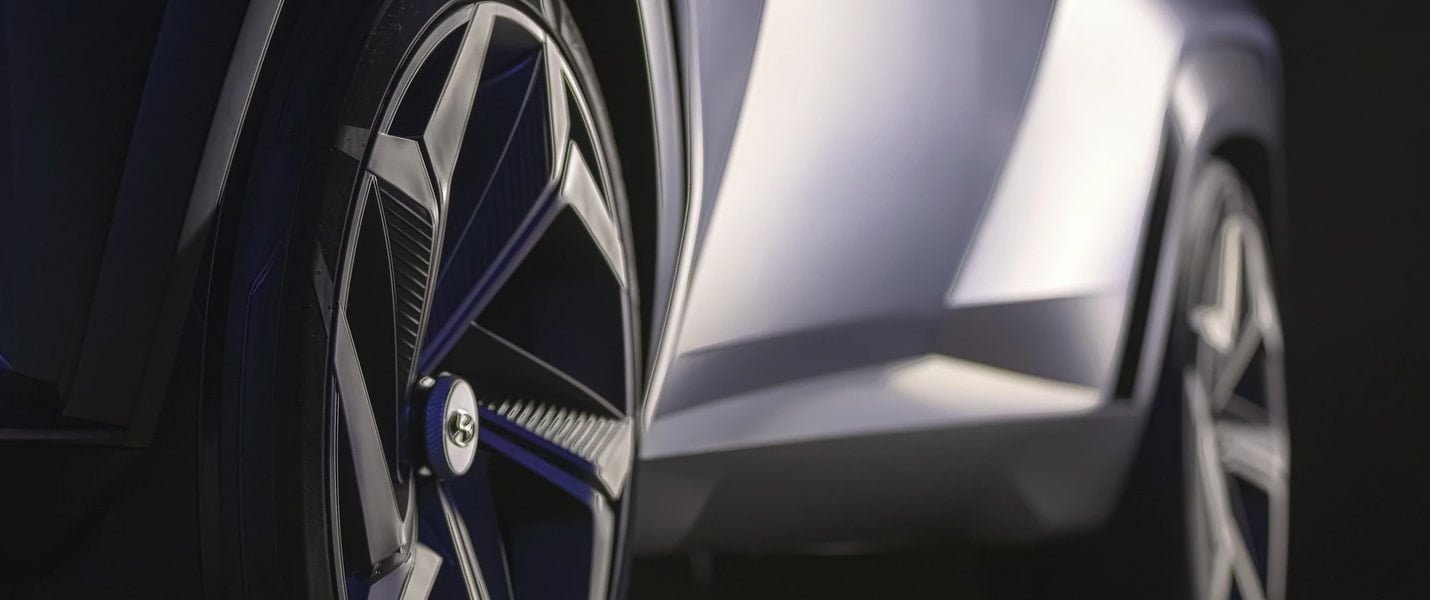

bluemacaw paint

The role of epoxy primer

Epoxy primer is an anticorrosive coating with epoxy resin as the main film-forming substance, which is used as a primer, suitable for carbon steel, cast iron and other iron substrates, and has the functions of anti-corrosion, anti-rust and salt spray resistance. The adhesion of epoxy primer is relatively good, and if it is used in metal materials such as steel, it will play a role in anti-rust and anti-corrosion; If it is used for epoxy flooring, it is mainly used to cover the bottom to prevent groundwater, bubbles, oil stains, etc. from seeping up, causing epoxy flooring to blister and fall off.

Application of epoxy primer

In addition to the excellent insulation and excellent chemical stability of solvent-based epoxy coatings, solvent-free epoxy primers have been greatly improved in terms of adhesion, toughness, impact strength and peel resistance. There is no solvent volatilization during construction, and the degree of film formation can reach more than 200μm at one time, and there is no pinhole disadvantage. Save energy and protect the environment. Solvent-free epoxy coatings have many advantages such as high strength, high solid content, good anti-corrosion performance, simple construction process, and no environmental pollution. It is mainly used in heavy anti-corrosion fields such as urban pipeline anti-corrosion, buried pipeline internal and external anti-corrosion, joint repair, elbow, pipe body buried pipeline anti-corrosion overhaul, etc.

Solvent-based epoxy primer is a two-component paint composed of medium and low molecular weight epoxy resin, anti-rust pigment filler, solvent, additives, etc., and hardened with amine curing agent.

- In the construction of epoxy primer, it is necessary to properly clean the grease and moisturize the cleanliness of the construction surface; The second is the need to smooth the corners, because the epoxy primer tends to flow away from the sharp corners during construction.

- When applying epoxy primer, it can only be used on the surface of the approved paint film, and it needs to be clean and dry; After the construction is completed, it is best to ensure that the ambient temperature is above 0 degrees Celsius, which is conducive to the drying of the epoxy primer.

- Finally, the service life of the epoxy primer depends to a large extent on good construction, therefore, in the construction, it is best to pay attention to details, such as rivets and jump welding parts need to be extra careful.

How to care for epoxy primer

- Employees walking on the floor should wear cloth shoes or soft material soles to avoid damage to the floor.

- When using large equipment such as push carts and forklifts, don’t go too fast, and hit the steering wheel lightly when turning.

- After a long period of use, the floor will inevitably appear to be painted off and scratched, and it should be repaired in time to prevent greater damage.

- The wheels of the cart or pallet truck can be used with elastic rubber wheels inside and outside the plant.

- Generally, the newly made floor can be used after ten days, during which water or other solutions should be avoided from spilling on the ground.

- When cleaning the ground, use a dry and wet vacuum cleaner with good soft water absorption, and if there is oil stains, you can use water or detergent to clean.

Precautions for using epoxy primers

- When the epoxy primer is opened and blended, it needs to be used within 2 hours, and the dosage must be controlled.

- When using epoxy primer, it is best to be able to spray with high-pressure airless, but the conditions are limited, so that air spraying will be used, which can make the paint film of the wall more flat.

- The epoxy primer should be stored in a cool and dry place, so that it is less likely to deteriorate, and the storage time of the epoxy primer is usually about three years.

- When blending the primer, it is necessary to mix according to the proportion on the instructions, if it is too thick after blending, you can write the thinner into it appropriately.

- When using spraying or brushing, ensure that every corner can be coated to prevent any leakage.

- When using epoxy primer, the content that needs to be diluted is about 25~30% of the total amount of paint; The amount of paint that needs to be occupied by brushing is about 10% of the total amount of paint.

- When the painting stage is finished, you need to wait for about 5-7 days to ensure that it can be completely dry. If it is raining, it is better not to carry out construction, the effect is relatively poor.