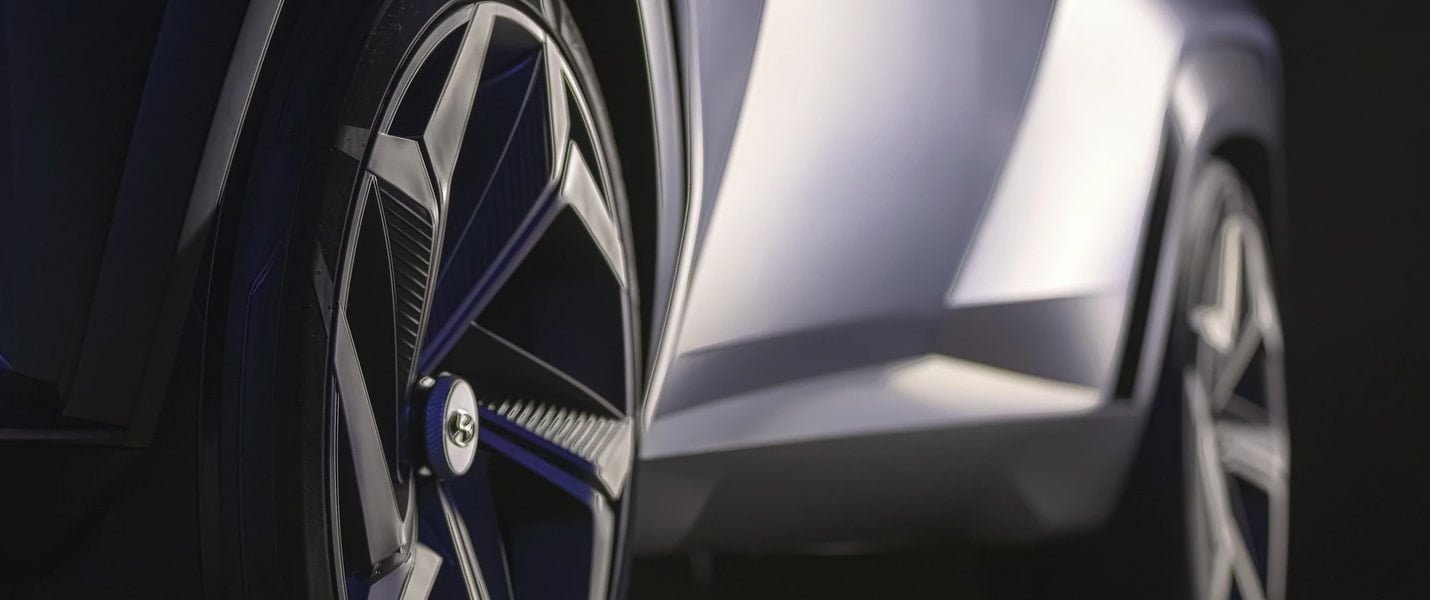

bluemacaw paint

Acrylic polyurethane paint not only has a certain protective effect, but also has a certain decorative effect. Acrylic polyurethane paint should be durable, lightfast, color-retaining, and gloss-retaining. The topcoat is in contact with corrosive media (air, moisture, ultraviolet rays, chemicals, etc.), so its protective performance is required. The paint film should have a certain mechanical strength, have a certain hardness, and can be polished, sanded, and waxed to obtain a highly decorative paint film. The color of the paint film should be bright and full. Applications include docks, ports, oil production platforms, underground metal structures, oil tanker oil and water tankers, buried pipelines, etc.

Features:

- Low pollution: advanced coating composite technology, the coating film is difficult to pollute

- High weather resistance: greatly improve weather resistance and water resistance, and the service life is more than 10 years

- Excellent adhesion: unique molecular structure, excellent adhesion, suitable for a variety of substrates

- Excellent workability: compared with ordinary oil-based paint, it has less peculiar smell, can improve the working environment, and can be constructed with a variety of coating tools

- The drying time is short, the low temperature workability is good, and the construction period is effectively shortened

Construction technology

Open the barrel and stir: after opening the barrel, stir the paint until there is no sediment at the bottom of the barrel, and mix and stir according to the ratio of coating: curing agent = 4:1 (weight ratio), and can be constructed after 15~20 minutes of curing, if the paint is indeed too thick, you can appropriately add XHDAC503 special diluent for polyurethane, the dosage is 5~15%, it is strictly forbidden to dilute with water, alcohol, banana water and gasoline, etc., and immediately after the paint is used, it is tightly sealed to prevent moisture deterioration.

- Surface treatment requirements: steel structure, substrate treatment requirements to reach the national standard Sa2.5 or above, or manual rust removal to St3 or above, can also use chemical rust removal, no oil, no rust, no debris, dry and clean.

- Theoretical consumption: If the influence of coating environment, coating method, coating technology, surface condition and structure, shape, surface area size and so on is not considered during actual construction, the general consumption is 0.20kg/㎡.

- The best construction temperature is 0~35 °C, the relative humidity is ≤85 °C, and the construction is not allowed under the conditions of rain, fog, snow and serious dust. 5. After the first coating, it is best to wait for more than 24 hours before coating the second coating, and the construction site can only be put into use after curing for seven days under normal temperature conditions.

Transport & Security Measures

- When the product is transported, it should be protected from rain and sunlight exposure to avoid collision, and should comply with the relevant regulations of the transportation department.

- The coating is water-based paint, and there is no risk of combustion and explosion under normal circumstances, but ventilation should be strengthened to improve the coating environment.

- Because the paint liquid is not harmless, effective measures should still be taken to prevent the skin from coming into contact with the eye and the paint (such as applicable work clothes, gloves, goggles, masks and protective oil, etc.). If the product comes into contact with the skin, wash thoroughly with warm water, soap and an appropriate industrial detergent, and if the eyes are contaminated, wash with water for at least 10 minutes and seek medical attention immediately.

- It is recommended to wear a ventilation mask to avoid inhaling paint mist and harmful solvent gases, especially when working in a poorly ventilated environment, and carefully dispose of old paint barrels to avoid polluting the environment

- Fireworks are strictly prohibited at the construction site.