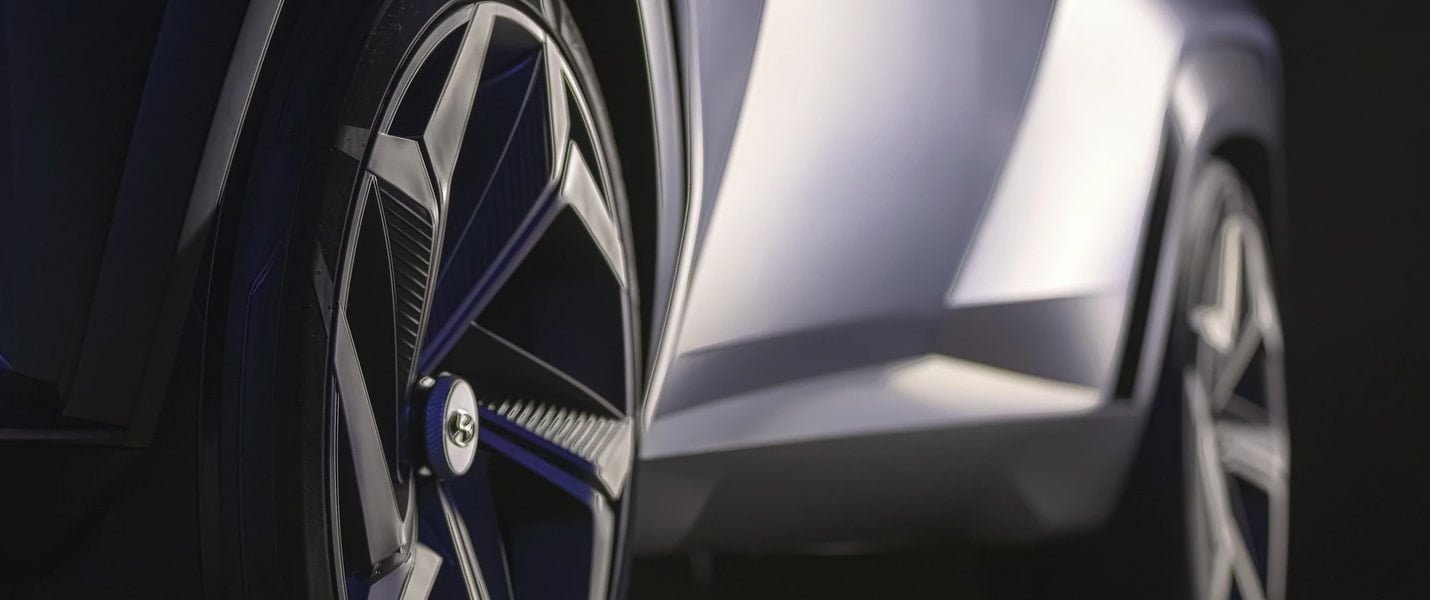

bluemacaw paint

1.Beautiful appearance. The paint film is required to be plump, with gorgeous and soft luster, good vividness, and a variety of colors that conform to the trend, making its appearance more pleasing to the eye and giving people a sense of beauty.

2.Excellent weather resistance and corrosion resistance, suitable for various temperatures, exposure and wind and rain erosion, and keep no loss of gloss, no discoloration, no blistering, no cracking, no shedding, no powdering, and no rust under various climatic conditions. The service life of the paint film is generally greater than 10 years.

3.Excellent construction and matching. Automobile paint is generally multi-layer coating. Because single-layer coating generally cannot achieve good performance, it requires good adhesion between each coating and no defects.

4.Excellent mechanical properties. Adapting to the high speed, multiple shocks and strains of the car, the paint film is required to have good adhesion, hardness and flexibility, impact resistance, bending resistance, scratch resistance, friction resistance and other excellent properties.

5.Excellent scrub resistance, stain resistance and good repairability. It is required to be resistant to brush, soap, and detergent cleaning, and leave no traces after contact with other common stains.

Asphalt coating is a coating with natural asphalt or artificial asphalt, with or without oil as the main film-forming material. Asphalt is a thermoplastic material and a long-standing coating variety. It has been widely used because of its rich material sources, low price and convenient construction. The main varieties are pure asphalt paint, oiled asphalt paint, and resin-added asphalt paint. Its main features are: excellent water resistance, good chemical resistance and insulation and heat resistance. It is a very good protective and anti-corrosion decorative coating.

Phenolic resin coating Phenolic resin coating is a coating made of phenolic resin or modified phenolic resin and dry vegetable oil as the main base material, and different types of drying agents, pigments and auxiliary materials are added according to the different raw materials used. The coating can be divided into alcohol-soluble phenolic resin coating, oil-soluble pure phenolic resin coating, modified phenolic resin coating and water-soluble phenolic resin coating.

Alkyd resin coating Alkyd resin coating is a type of coating with alkyd resin as the main film-forming material. Alkyd coating has a wide range of uses and strong adaptability. Its main properties are: good weather resistance after the paint film dries, not easy to age, long-lasting gloss retention, friction resistance, strong flexibility, spraying and brushing construction methods can be used, and after drying, oil resistance, water resistance and insulation are greatly improved.

Amino resin coating is a type of coating with amino resin and alkyd resin as the main film-forming substances, and one of the main varieties of thermosetting synthetic resins. There are three types of amino resins used to prepare coatings: one is melamine formaldehyde resin, and the other two are urea-formaldehyde resin and benzoic melamine formaldehyde resin. However, if the coating is prepared with amino resin alone, the paint film after heating and curing is hard and brittle, and the adhesion is also poor. Therefore, it must be used in combination with other resins.

Nitro paint Nitro paint is a type of coating with nitrocellulose as the main film-forming substance, usually called spray paint. Although there are many varieties of nitro paint, they can be divided into two categories in terms of performance and use: external base paint and internal nitro paint. Due to the different proportions of nitrocellulose in the coating, different modified resins, and different types of plasticizers, the performance and use are not exactly the same. Its advantages are: the coating film dries quickly, is hard and wear-resistant, has good chemical resistance, water resistance, weak acid resistance, gasoline resistance, alcohol resistance and good flexibility. By mixing appropriate plasticizers, soft nitro paint with good flexibility can be made, such as nitro leather paint.

Perchloroethylene resin coating Perchloroethylene resin coating is a coating based on perchloroethylene resin, and also includes other resins, plasticizers, stabilizers, pigments (varnish without pigment) and organic solvents. Perchloroethylene resin coating is a volatile coating. Its advantages are: natural drying is faster, inferior to nitro paint, and suitable for a variety of construction methods. It has excellent chemical resistance and can withstand 25% sulfuric acid, nitric acid and 40% caustic soda for several months at room temperature. It has good weather resistance, water resistance, humidity and heat resistance and good fire resistance.

Acrylic resin coating Acrylic resin coating can be made into two types of coatings: thermoplastic and thermosetting due to the different monomers selected. Thermoplastic acrylic resin coating has good hardness, light color and no yellowing, and good durability. Mainly used for aluminum alloy surfaces that require good weather resistance and gloss retention. Thermosetting acrylic resin coatings are mostly cured with amino resins, epoxy resins, polyurethane oligomers, etc. as curing agents. The paint film has good mechanical properties, fullness, weather resistance, high hardness, good color retention, high brightness, and certain water and oil resistance. It is cured by baking.

Epoxy resin coatings Epoxy resin coatings have a variety of excellent properties, are developing rapidly, have many varieties and large output. In order to better improve its performance, other resins are often added for modification to obtain coatings that better meet the requirements of use. The outstanding performance of epoxy resin coatings is strong adhesion, especially stronger adhesion to metal surfaces, and good chemical corrosion resistance.

Polyurethane coatings The polyurethane coating industry is developing rapidly. Due to the decline in raw material costs and good performance, it has become an extremely important type of coating with rapid growth in variety and output. Polyurethane coatings have excellent mechanical properties, the paint film is hard, bright, plump, wear-resistant and has good adhesion; it has good anti-corrosion properties, the paint film is acid and alkali resistant; it can be cured at room temperature or heated; it has good electrical properties; it can be used with a variety of resins to make a variety of polyurethane coatings.